download article

download articleTurning Up The Heat On Food Grade Fluids

Article index

| Operational Challenges | |

| Food Grade Fluids | |

| Managing the Risk | |

| Food Grade Performance | |

| System Support | |

| Food Safe Solution |

Regulating cooking / deep-frying temperatures is of prime importance to snack manufacturers. The slightest variance in temperature can lead to foodstuffs being either under- or over-cooked, affecting product quality, taste and potentially, safety for consumption. Consequently, cooking / deep-frying at the wrong temperature can be costly for snack manufacturers in terms of product wastage and lost production time. Product recalls may even be necessary if a product not fit for human consumption enters the market. This can have a detrimental impact on customer relationships and brand reputation, as production deadlines are missed and product quality and safety deteriorates.

Operational Challenges

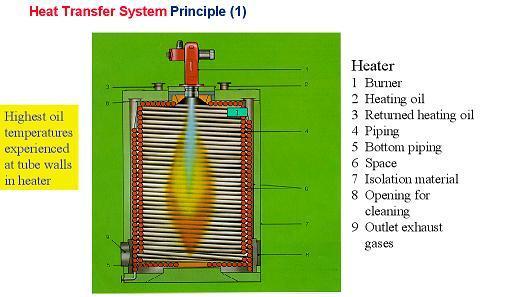

As many snack manufacturers will know, maintaining the correct cooking temperature even when using heat transfer systems can be a challenging task. Peter Wardle explains: “The heat transfer fluid, used in the system which separates the heat source from the cooking surface, operates under extreme temperatures, which can affect the fluid’s viscosity and flash point. Thermal and oxidation stability of the fluid become the most important factors. Using an inappropriate fluid can lead to a number of operational problems such as uneven heat transfer, resulting in irregular cooking/deep-frying temperatures.”In common with most food processors and producers, snack manufacturers are also tasked with ensuring high levels of food safety, while trying to overcome operational challenges and increase equipment performance and efficiency. Just one incident of food contamination can have catastrophic effects for any food company and has the potential to destroy a company’s hard-earned reputation for quality and safety.

For snacks producers, one of the biggest threats of food contamination comes from the use of non-food grade fluids in heat transfer systems; yet, this risk can be significantly reduced by switching to food grade heat transfer fluids.

Food Grade Fluids

Heat transfer systems operate in close proximity to foodstuffs, presenting a real threat of incidental fluid contact, which can jeopardise food safety and consumer health. Peter Wardle comments: “Traditionally, many operators have used non-food grade heat transfer fluids in their systems, as these fluids have not been subjected to the extra refining steps needed for food grade lubricants, which can sometimes impair fluid performance. However, operators no longer need to make this compromise as high quality food grade fluids such as Shell FM Heat Transfer Fluid 32 and Shell Cassida ® Fluid DC 32 (a synthetic product) offer excellent performance benefits, while reducing the risk of unacceptable food contamination through accidental fluid contact.”

After discussions with leading Original Equipment Manufacturers (OEMs) and extensive R&D work, Shell lubricants experts have been able to develop food grade fluids for use in closed and unpressurised heat transfer systems. The food grade fluids have been specifically designed to perform in extreme temperatures, offering high oxidation and flash point properties. Shell FM Heat Transfer Fluid 32 has been developed for use at temperatures up to 340 ºC, while Shell Cassida Fluid DC 32 has been developed for slightly lower operating temperatures.

To help snack manufacturers increase levels of food safety, both fluids have been formulated using specially-selected, food-grade-approved additives and base fluids. This composition means that they are colourless, odourless and tasteless and will not impair food safety or quality, should they accidentally come in to contact with food in quantities less than the US Food and Drug Administration’s maximum permitted level of ten parts per million for H1 lubricants. Shell Cassida Fluid DC 32 also carries NSF 3H approval which means that higher levels of contamination of food are acceptable before the food is deemed to be unfit for sale/consumption under FDA regulations.

Managing the Risk

Although good equipment maintenance and HSE programmes can help reduce the risk of food contamination, it cannot always protect against the threat of accidental fluid contact. Peter Wardle explains: “Extreme operating temperatures and 24/7 production place a great deal of pressure on heat transfer systems, which can lead to cracks in the furnace or heat exchanger, hot spots and corrosion in the system and damage to gaskets and seals. This can increase the risk of accidental fluid contact through drips or leakage and can easily go unnoticed until production performance is hampered or even worse, a public complaint is made.”Approved for use in Halal and Kosher food production, Shell FM Heat Transfer Fluid 32 and Shell Cassida Fluid DC 32 have received HT-1 registration from the NSF International; complying with the requirements of US FDA 21CFR 178.3570. The synthetic formula used is compatible with elastomers, gaskets, seals and paints used in heat transfer systems, further reducing the risk of accidental fluid exposure through drips or leakage.

Food Grade Performance

As well as increasing levels of food safety during production, high quality food grade lubricants can help to increase equipment uptime, performance and efficiency, while helping to reduce maintenance costs. “Shell FM Heat Transfer Fluid 32 and Shell Cassida Fluid DC 32 offer a high resistance to thermal cracking, enabling the fluids to maintain viscosity during heat transfer. This reduces the potential for deposits in the system, which can lead to hot spots and overcooking of the foodstuff. Hot spots are also a leading cause of corrosion, which can result in long periods of unscheduled downtime,” adds Peter Wardle.Shell heat transfer fluids have also been developed to cope with the presence of oxygen in heat transfer systems. The fluids’ high oxidation resistance and flash point properties help reduce oil decomposition, a major cause of irregular heat transfer which can adversely impact on food quality, safety and production times.

System Support

In assisting snack manufacturers in optimising heat transfer fluid performance and achieving high levels of food safety, Shell lubricants companies offer a comprehensive product service package. Comments Peter Wardle: “Shell lubricants companies are able to carry out a full Shell Lubricant Contamination Control Point (LCCP) survey, based on Hazard Analysis and Critical Control Point (HACCP) principles to identify contamination hotspots. This approach ensures that heat transfer system operators fully understand where the risks of contamination are most likely to occur and how they be reduced using a food grade fluid.”In helping snack manufacturers safely make the switch from non-food to food grade fluids, Shell lubricants companies provide fluid change and disposal, machine and vacuum cleaning and their specialist oil monitoring service, Shell eQuip. Peter Wardle adds: “To profit from the performance and safety benefits of food grade fluids, operators cannot simply top their systems up. Systems need to be properly cleaned and emptied of the non-food grade fluid. The replacement fluid should then be monitored on a regular basis to ensure that it is offering optimal performance.”

Food Safe Solution

Thanks to the use of high quality food grade heat transfer fluids, supported by the necessary implementation and monitoring support, operators no longer need to compromise performance for food safety. In many cases, the excellent performance properties of Shell FM Heat Transfer Fluid 32 and Shell Cassida Fluid DC 32, mean that operators can increase operational efficiency and uniformity of heat transfer, while reducing maintenance costs and improving levels of food safety. Ultimately, this will help snack manufacturers to protect their product, process and brand against the threat of contamination.For more information: FUCHS LUBRICANTS GmbH

back to top

back to top

companies

companies