download article

download articleSlaughter automation

Article index

MPS designed and build F-line for killfloor use so it is NOT a modifed industrial robot.

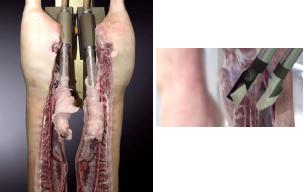

The MPS F-line: automate pre cutting, belly opening, rectum drilling, neck cutting, leaflard removal, splitting and marking. These robots take over the hard tasks in the evisceration line. Those are employable from 200 to 1,250 pigs per hour. At this moment more than 200 F-line machines are installed world-wide, including Europe, North America, China and Japan.

Research has shown a consisted contamination reduction (improving shelf life), yield improvements (more saleable meat) and labour reduction (lower costs meat) which would under normal commercial circumstances result in a short payback period (< 2 years).

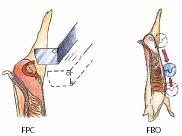

F-line Pre Cutter: Cutting pelvic bone

The MPS FPC operates with a special designed static knife which makes the .rst cut in the still closed carcass. The MPS FPC makes a ideal pre-cut for the MPS FBO Belly Breast Opener.

F-line Belly and Breast Opener: Opening of belly and breast

The MPS FBO opens the belly and finally cuts the breastbone into two symmetrical parts.

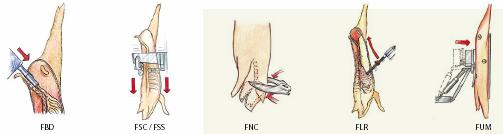

F-line Bung-Dropper: Drills the fat-end

The MPS FBD loosens the fat-end and the rectal track is guided in the Bung Guiding System (optional) for manual handling together with the white organs.

F-line Splitting Splitting Saw: Splitting of the carcass

The MPS FSC/FSS divides the carcass in two equal halves.- The FSC performs its task by chopping with a double knife;

- The FSS uses a circular saw.

F-line Neck Cutting: Cutting of the head

The MPS FNC opens the neck meat and cuts the vertebrae connection between head and back of the carcass.

F-line Leaflard removing: removing of the leaflard

The MPS FLR pulls and removes the leaflard from a split (up to the head) carcass. The machine is installed after the veterinary inspection.

F-line Universal Marking: marks the carcass

The MPS FUM marks the two carcass halves with fixed veterinary stamps and flexible code.

For more information: MPS Meat Processing Systems

back to top

back to top

companies

companies