Dit artikel is nog niet beschikbaar in de door u gekozen taal

Synthetic belts (PVC, PU, PE, silicone, rubber)

Synthetic belts are designed as endless belts. Carriers, guide profiles, wavy edges and trimmings can all be welded onto the belt. Synthetic belts are driven by a friction roller/drum motor which is often higher in the middle (camber/crowning).

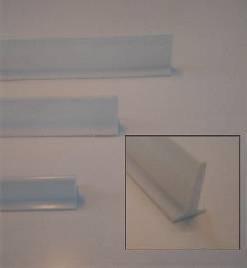

Figure 1. Example of synthetic belt.

| Function | Synthetic belts mostly run straight, down or up. Must be food approved. Synthetic belts have a homogenous surface, which is easy to clean. Damaged belts lead to poor hygiene. |

| Construction | The belt needs guidance to stay in place. The belts are made from synthetic material and are often reinforced with textile fibres encapsulated in the belts. It is important that the encapsulated textiles are kept dry as they may otherwise be conducive to the spread of bacteria. Damaged belts lead to poor hygiene (frayed edges). To avoid frayed edges, trimmings can be welded onto the belt. Carriers can be extruded from pure synthetic material or textile reinforced. The latter should always be provided with trimmings. Cut textile reinforced belts should always be sealed. In connection with curve conveyors, special attention must be paid to the machine design. An extruded, purely synthetic guide profile can be welded to the backside of the belt for guidance. |

| Cleanability | The belts are easy to clean as long as they are not damaged. Cleaning can be carried out manually or automatically through CIP (Cleaning In Place). The design must allow the release of the initial tension so that the belt can be removed or lifted and cleaned on the underside. It must be possible to dismount the belt for cleaning, when it is supported by a plate. It cannot be cleaned from below and from both sides unless it is dismounted. |

| Service/maintenance | Check the construction for impurities to avoid restricted guidance of the belt. Make sure that the initial tension of the belt is correct to avoid drive drum slippage. Ensure that the tensioning during operation is correct, that the tensioning sections are intact and fully functional, and that all rotating components (drive drum, tail and return roller) are clean and functional. Check the belts for damage. |

The following figures show examples of modular belts and attention points in terms of hygiene.

|

|

|

|

|

|

| Figure 6. Cut textile reinforced carrier. The seal is broken and represents a hygiene risk. Should be resealed. |

Figure 7. The edge sealing has been removed, and the belt is fraying, which represents a hygiene risk. Should be resealed. |

Figure 8. Damaged belt due to wear. The coating is worn off and there is direct contact with the textile reinforcement, which is a hygiene risk. The belt must be replaced to ensure a sealed/uniform surface that will not be conducive to bacterial growth, and which can be easily cleaned.

Source: www.staalcentrum.dk

naar boven

naar boven

bedrijven

bedrijven