Dit artikel is nog niet beschikbaar in de door u gekozen taal

Apron belt (= apron chain)

Apron belts consist of apron plates that are hinged to the underside with a single or double hinge. Apron belts are driven by a chain sprocket. Belt width and apron plate width are identical. Note: Apron belts are not recommended for direct food contact.

Figure 1. Example of apron belt.

| Function | Apron belts can run in straight lines or in curves. Apron belts cannot be recommended for direct food contact as the fastening of the steel pin makes cleaning around the hinge difficult (see figure 3). The apron belt will have a droop immediately after the drive sprockets (the same applies to modular belt conveyors). This is to ensure that the chain/belt is drawn tight towards the sprocket. At the same time, the droop will compensate for varying chain or belt length as a result of the load, temperature, wear, etc. |

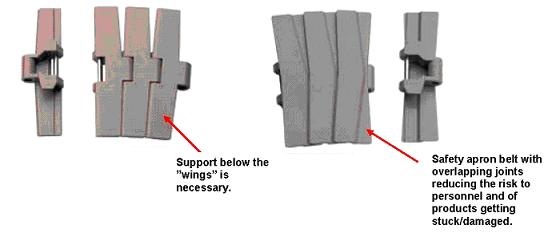

| Construction | Apron belts are constructed from plastic parts that are joined in endless lines by means of pins. The pins are normally produced in stainless steel. The stainless steel pin is fastened with a press fit or riveting. Using apron belt for curves will lead to relatively large openings which may constitute a safety risk for personnel or cause products to get stuck/damaged. Safety belts with overlapping joints will reduce the above-mentioned hazard (see figure 2). The support below the “wings” is necessary. |

| Cleanability | When choosing detergents, it should be taken into account that apron belts are normally made of POM (polyoxymethylene = acetal plastic) which has limited resistance to chlorine-containing detergents. The fastening of the steel pin makes it difficult to clean around and inside the hinge. |

| Service/maintenance | Generally, apron belts are characterised by requiring little continuous maintenance. The mentioned droop eliminates the need for regular tensioning. In the case of substantial wear, the droop can be reduced by removing one or more joints. Belts are usually replaced due to wear. In this connection, the bendings on the underside can be used to indicate the extent of the wear. Alternatively, reduced engagement with the drive sprocket may indicate wear and subsequent increased. |

Figure 2. Normal apron belt (left) and safety apron belt (right).

Figure 3. Apron belts cannot be recommended for direct food contact as the fixation of the steel pin makes cleaning around the hinge difficult.

Source: www.staalcentrum.dk

naar boven

naar boven

bedrijven

bedrijven