| News |

Coste y carga ambiental reducido con CCS, el sistema central único de la limpieza

lunes 7 mayo 2007

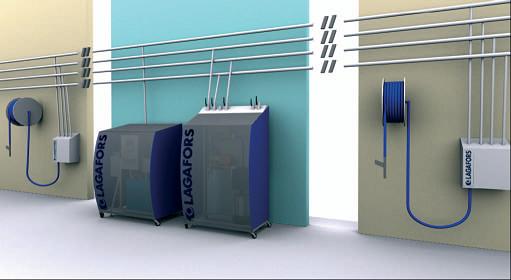

Lagafors Fabriks AB has announced the global launch of its new Central Cleaning System, CCS, enabling the food industry to obtain ultimate hygiene at reduced cost and environmental impact, in an improved working environment.The Central Cleaning System (CCS) meets most customers’ demands for improved effi ciency in cleaning, whilst not compromising performance or quality. The CCS is the result of years of research and development activities. The system was to a great extent funded by the EU, to ensure that the newly introduced water saving directives can be implemented.

Advantages

By combining the components of the CCS concept, consisting of the newly developed Variable Chemical Centre (VCC) and patented Variable Pressure System (VPS), customers can enjoy cost savings of up to 35% compared to most present cleaning systems and methods. These savings, and a decreased environmental impact, are achieved thanks to reduced use of warm water, chemicals and less wastewater. The central component, the Variable Pressure Pump (VPP 8090), provides the pressure and fl ow, where needed, for up to 5 simultaneous users. It also provides a great ergonomic advantage for the operators compared to the strong pressure peaks, and even injuries, experienced with traditional pressure cleaning equipment. The hydraulic operation of the system secures high reliability and reduced maintenance cost.

“The new Central Cleaning System from Lagafors delivers on its promises”, says Göran Paulsson, Production Manager at Torsåsens Fågelprodukter AB (Torsåsens Poultry Products AB). “We have tried it in our production facilities for a period of six months and are highly satisfied, both from an operational point of view and the quality of the end result. As a consequence of these tests we have now ordered the first commercially available unit”, Göran Paulsson concludes.

companias

companias

más

más