This article is not yet available in the language you selected

Modular belts

Modular belts consist of modules that are assembled by means of cross pins. The modular belt is driven by a chain sprocket or a toothed, vulcanized rubber coating. The modules can be assembled into different lengths and widths. |

|

Figure 1 and figure 2. Examples of modular belts.

| Function | Modular belts can run in straight lines or in curves. By using curve running belts, it is possible to combine straight and curved sections in one belt and thus reduce the number of drive stations, which is an advantage in terms of hygiene. There should be as few joints/modules across the belt as possible. Antimicrobial substances may be cast into the material, but please note that these must be food approved for product contact. |

| Construction | Modular belts are based on a traditional load-carrying structure that is adapted to design requirements for the modular belt. The modular belt consists of plastic modules that can be put together using different types of joints, designed for specific purposes. The choice should depend on the task, products and environment (chemistry, temperature, pH, time, concentration of detergents). Belt lift can be used if the construction cannot be made sufficiently open. The modular belt will have a droop immediately after the drive sprockets (the same applies to apron belt conveyors). This is to ensure that the chain/belt is drawn tight towards the sprocket. At the same time, the droop will compensate for varying chain or belt length as a result of the load, temperature, wear, etc. |

| Cleanability | The belt may prove difficult to clean. Cleaning can be carried out manually or automatically through CIP (Cleaning In Place), i.e. nozzle cleaning with screening of the area to prevent the spread of dirt. Make sure that the proper types of nozzles are used. The nozzles can be mounted both outside and in between the chains dependent on belt type. Make sure to select the proper nozzles, correct pressure, number and location of nozzles. A nozzle beam must be placed so that impurities are washed out of the belt when it opens on the return roller. Also make sure that product residue is washed off the inside, underside and screens so that any product residue is removed after cleaning. If rotating brushes are used for cleaning, they should be in a colour different from both the product and the belt. The brushes must be cleaned and heat-treated, or placed in a vat with a suitable disinfectant, after use. |

| Service/maintenance | Be aware of wear and damage and increased belt width (adjustments are particularly important early in the belt lifetime and on temperature changes). Nozzles must be dismounted and cleaned regularly. The washwater particle filter must be cleaned regularly. |

The following figures show examples of modular belts and attention points in terms of hygiene.

Figure 3. Example of a modular belt with a drum motor drive with sprockets. This is a excellent solution as long as the belt can be lifted for cleaning.

Figure 4. Underside of a modular belt (on the return side) with product residue before cleaning. The belt can be difficult to clean.

|

|

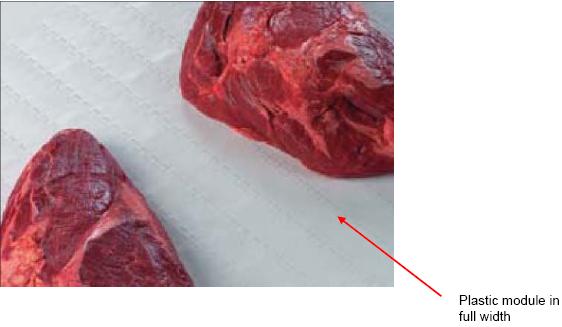

Figure 5 and figure 6. Modular belts where the individual joints are shorter than the belt width. The belt is more difficult to clean than belts where the width of the joints is identical to the belt width. The small picture shows how dirt settles between the short joints.

Figure 7. Modular belt where the length of the modules is identical to the belt width. This is an advantage in terms of hygiene as the number of joints is reduced.

Source: www.staalcentrum.dk

back to top

back to top

companias

companias